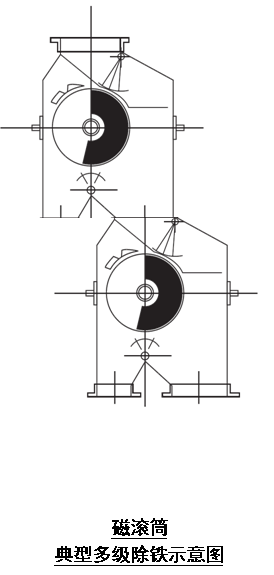

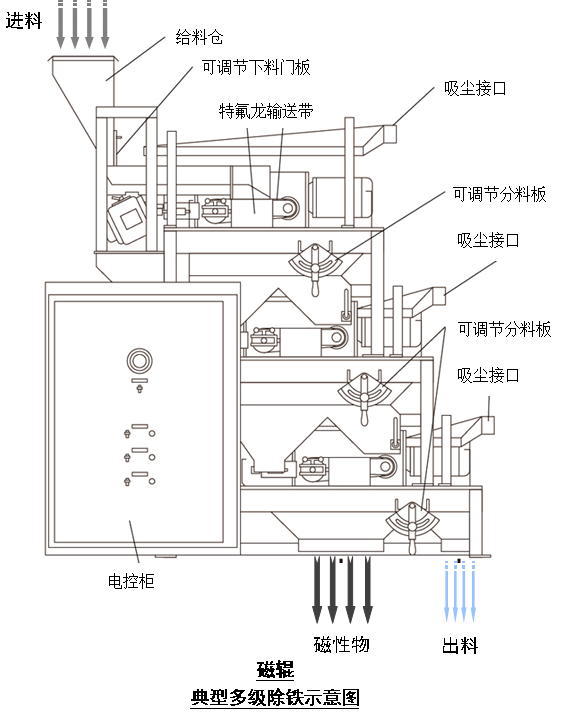

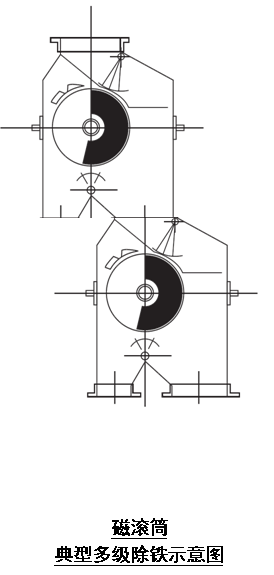

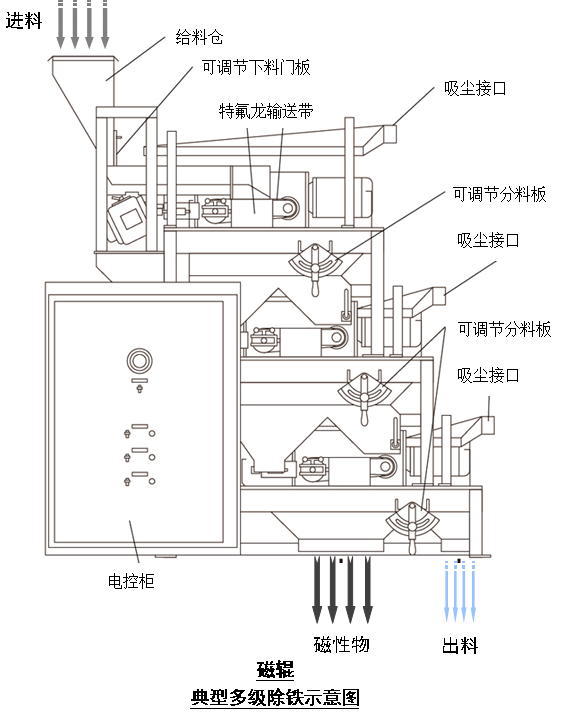

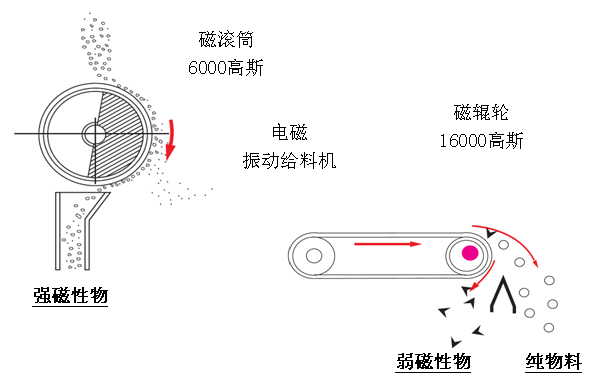

Magnetic Drum & Roller separator

permanent magnet drum:is used to automatically remove fine ferromagnetic pollutants mixed in powder, granular and small bulk materials, including mechanical iron filings, stainless steel filings, rust, iron oxide impurities, etc. The internal magnetic system (160-180) of the permanent magnet drum is in a fixed position, and the external barrel is rotating. When the material passes through the drum, the miscellaneous iron is adsorbed on the surface of the drum skin. They move back with the operation of the drum skin, and fall off the drum skin after leaving the magnetic field area. Non-magnetic materials are affected by centrifugal force and gravity. Fall on a natural trajectory to achieve separation.

permanent magnet roller wheel:The magnetic roller wheel is made of NdFeB strong magnetic material in the form of a roller wheel. The material is uniformly delivered to the Teflon belt through an electromagnetic vibration feeder. When the material passes through the magnetic roller wheel, the magnetic material is adsorbed and then thrown off under the roller wheel. The non-magnetic material is affected by centrifugal force and gravity and falls on a natural trajectory, thus realizing material separation.

characteristics

1. Continuous operation without manual cleaning of magnetic objects;

2. The front end adopts a magnetic roller to remove large particles and strong magnetic impurities to prevent the back end from scratching the Teflon belt;

3. The working field strength of the magnetic roller can reach up to 6000 Gauss, and the working field strength of the magnetic roller wheel can reach up to 16000 Gauss;

4. Modular structure design can realize multi-level continuous iron removal operation and improve work efficiency.

parameter

1. For detailed parameters, please contact our technical staff;

2. Material: SUS304/SUS316L